Premade Tea Bag Shaping Machine has a fully automatic integrated back sealing function, suitable for packaging various types of particles, tea, and powder, using plastic packaging bags, with a packaging speed of 12-17 bags per minute.

Model :

DL-DZK-1S-AVoltage :

AC220V/ 50HzPacking Speed :

8-12 Bags/minWeight :

120 KGWeight range :

1-25gWeighing error :

±0.2 gramPower :

800 WDimension :

550*550*1280mmBag Type :

Teardrop-shaped、Cube(Tofu)-shaped、Flat-shapedScale NO :

1 scale| Description |

Premade Tea Bag Shaping Machine has a fully automatic integrated back sealing function, suitable for packaging various types of particles, tea, and powder, using plastic packaging bags, with a packaging speed of 12-17 bags per minute.

| Specification |

| Model | DL-DZK-1S-A |

| Dimension | 55*55*128 cm |

|

Power Supply

|

1 KW |

| Weight | 120 KG |

| Voltage | AC220 V/50 HZ |

|

Packaging Speed

|

8-12 bags/min |

|

Weight range

|

1-25 g

|

| Weight Error | ±0.2g |

| Bag Length |

90-150 mm

|

| Bag Width |

55-90 mm

|

|

Final Bag Shape

|

Teardrop-shaped

|

|

-

|

Cube(Tofu)-shaped

|

|

-

|

Flat-shaped

|

If you have special need, it can be customized according to the needs of customers.

| Features |

1.Adopt professional customized industrial control system to help customers solve after-sales problems remotely;

2.Simple and easy to operate, various conventional packaging functions can be switched with one click;

3.Brand new weighing system, efficient and stable, with high weighing accuracy;

4.The packaging has a wide range of applications, and is suitable for all kinds of dry solid granular, block, flake, strip and other objects, as well as all kinds of tea products in small grams;

5.The whole machine adopts pure electric drive without pneumatic drive, which reduces stuck and air source cost consumption;

6.The operation noise is low and the operation is smoother than that of pneumatic drive.

| Application |

1.Conventional packaging products of this packaging machine: Tieguanyin, Dahongpao, Jinjunmei, Lapsang Souchong.

2.Green tea, etc., packaging of curly, cord-shaped, granular tea leaves. It is also suitable for packaging small materials such as corn, peanuts, rice, etc. Packaging functions include inner film, vacuum, shaping or nitrogen filling functions.

3.Suitable for packaging of various bag shapes, such as square, flat, drop-shaped and other bag shapes.

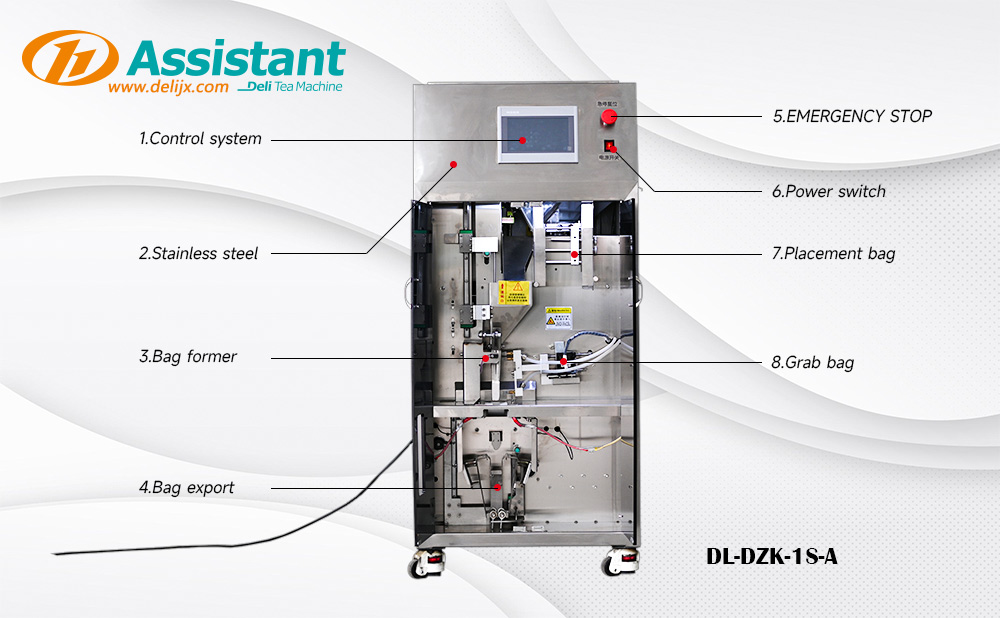

| Machine structure |

| 1 | Control system | 5 | EMERGENCY STOP |

| 2 | Stainless steel | 6 | Power switch |

| 3 | Bag former | 7 | Placement bag |

| 4 | Bag export | 8 | Grab bag |

| Product Detail |

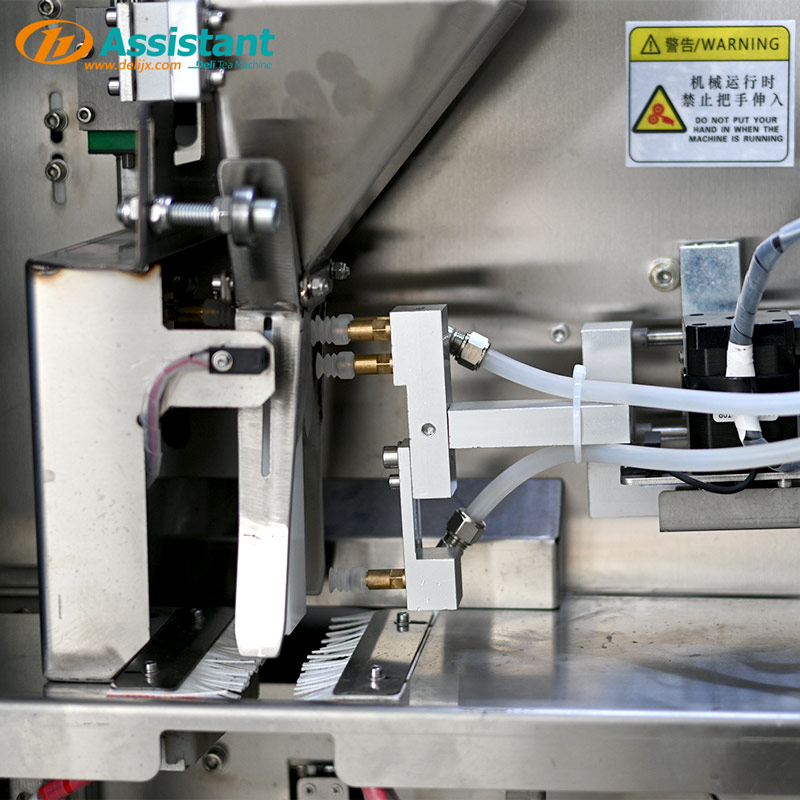

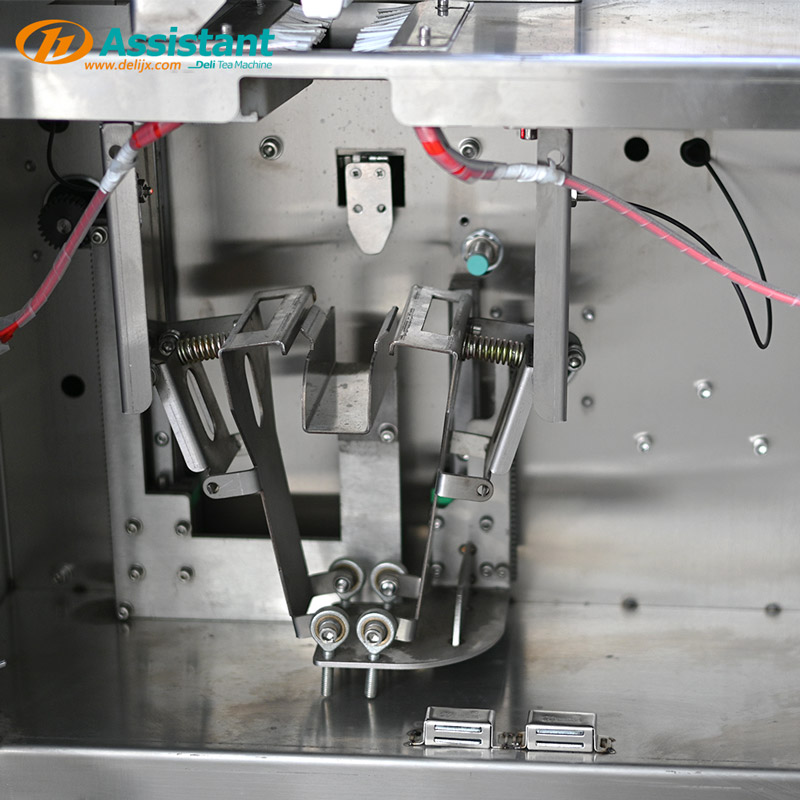

1.Bag former

The bag former is a component of the machine that shapes the pre-made tea bags before they are filled with tea. It ensures that the bags are properly formed and ready for filling.

2.Control system

The control system of the machine is responsible for managing and regulating the various functions of the machine, such as filling, sealing, and cutting. It ensures that the machine operates efficiently and accurately.

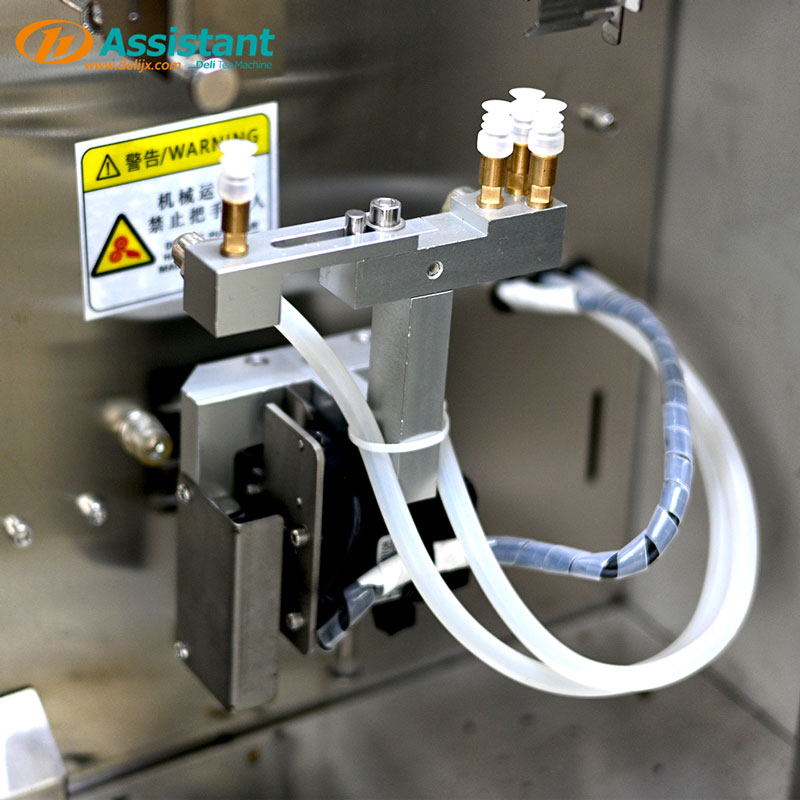

3.Grab bag

The grab bag mechanism is used to securely hold the pre-made tea bags in place during the filling and sealing process. It ensures that the bags remain stable and do not move around during operation.

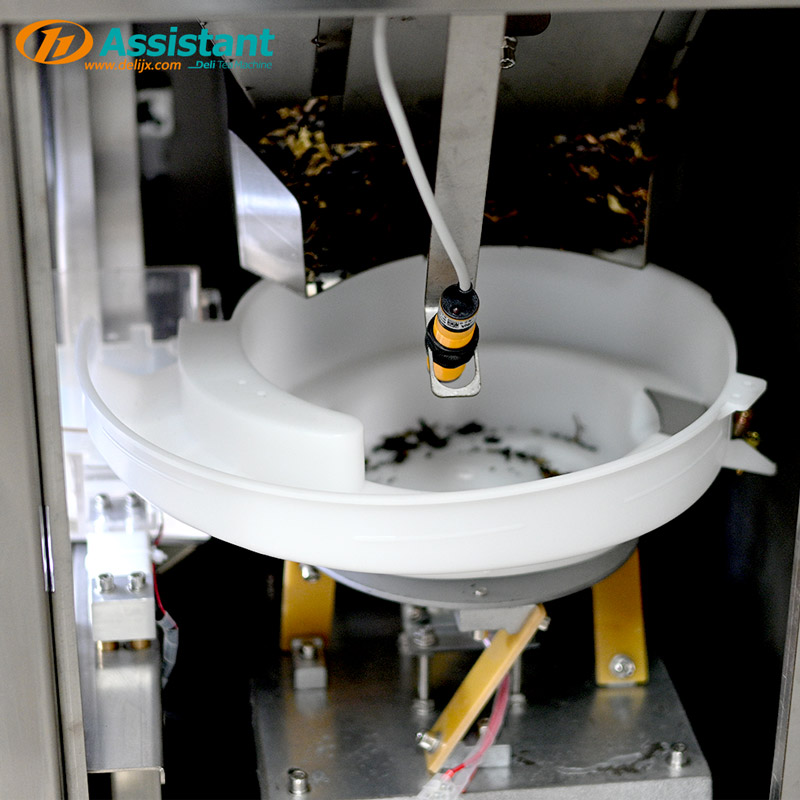

4.Electronic shaking sieve tray

The electronic shaking sieve tray evenly distributes tea leaves in pre-made bags for efficient and consistent packaging. It features automated operation, adjustable settings, durability, and high efficiency.

5.Bag export

The bag export mechanism is responsible for removing the filled and sealed tea bags from the machine once the packaging process is complete. It ensures that the bags are safely and efficiently exported from the machine for further processing or packaging.

6.Placement bag

The placement bag mechanism is responsible for accurately positioning the pre-made tea bags in the correct position for filling. It ensures that the bags are aligned properly for the filling process.

| CONTACT US |

If you are interested in this product, please contact us to get the price.

↑ ↑ Click the icon to get the latest price directly ↑ ↑

Tags :