As a medium-sized material packaging machine, it can be used for packaging granular and powder products such as tea, nuts, coffee, candy, industrial screws, etc. It has automatic packaging, automatic bag cutting, combined with filter paper and plastic film, and uses a back sealing bag making process. It can produce up to 20 bags per minute.

Model :

DL-DBZ-500Voltage :

220V / 50HZPacking Speed :

6-10 bags/minutesWeight :

250 KGWeight range :

20-500 gramWeighing error :

± 0.2gPower :

1.5 KWDimension :

1030*880*1730 mmScale NO :

1| ***DESCRIPTION*** |

This tea bag packaging machine is suitable for automatic packaging of various types of tea. It is primarily used for packaging plastic tea bags, with a packaging range of 20-500g. It features tea bag forming capabilities, shaping the tea bags into square shapes. This packaging is elegant and stylish, making it an essential automatic packaging machine for high-end tea packaging.

| ***ADVANTAGE*** |

The Automatic Tea Pouch Packing Machine is suitable for oolong tea, black tea, green tea, and other varieties, as well as for small quantities of large particle sizes in subcontracting.

It offers:

1. Full automatic sub-packaging and integrated packaging;

2. Double electronic scale design for a 100% increase in packaging speed;

3. Full PLC control panel for more intelligent and simple operation;

4. Counting function for accurate package calculation;

5. Fully automatic production without manual intervention during operation;

6. Packaging process that preserves material integrity without causing damage.

| ***SPECIFICATION*** |

| Model | DL-DBZ-500 |

| Voltage | 220V / 50HZ |

| Dimension | 1030*880*1730 mm |

| Power | 1.5 KW |

| Scale NO | 1 scale |

| Bag Length | 15-28 cm |

| Bag Width | 8-10 cm |

| Packing Speed | 6-10 bags/min |

| Weight Error | ± 0.2 gram |

| Weight range | 20-500 gram |

If you have special need, it can be customized according to the needs of customers.

| ***APPLICATION*** |

This kind of machine can efficiently package tea leaves with aluminum foil film, providing good protection for tea leaves. The aluminum foil film can help prevent moisture, oxygen, and light from affecting the quality of tea leaves, prolonging the shelf life of tea.

| ***Product Information*** |

| 1 | Touch screen | 4 | Switch button |

| 2 | Grab bag | 5 | Placement bag |

| 3 | Product export | 6 | Stainless steel |

| ***Product details*** |

1.Operation Control

Enables the setting of various packaging parameters such as packaging speed, bag size, and heat sealing temperature. Operators can adjust these parameters according to different tea varieties and packaging requirements to achieve optimal packaging results.

2.Heat sealing device

Perform heat sealing on the formed tea packaging bag to firmly seal the edges of the packaging bag together to ensure the sealing and freshness preservation of the tea. The heat sealing device usually uses heating elements such as heating strips, heating plates or ultrasonic generators to heat the edges of the aluminum foil film to a molten state, and then applies a certain pressure to make the molten film materials fuse with each other to form a sealed seal.

3.Cutting device

Cut and separate the continuously packaged tea bags from the packaging material to form individual packaging finished products. The cutting device usually uses tools such as blades, laser cutters or hot cutting knives to cut the packaging material according to the preset cutting position and length.

4.Aluminum foil film unwinding device

Store and release aluminum foil packaging film to provide continuous packaging materials for the packaging process. This device usually consists of an unwinding shaft, a braking device and a guiding device. The unwinding shaft is used to install the aluminum foil film roll. The braking device can control the unwinding speed of the aluminum foil film to make it work in coordination with other components of the packaging machine.

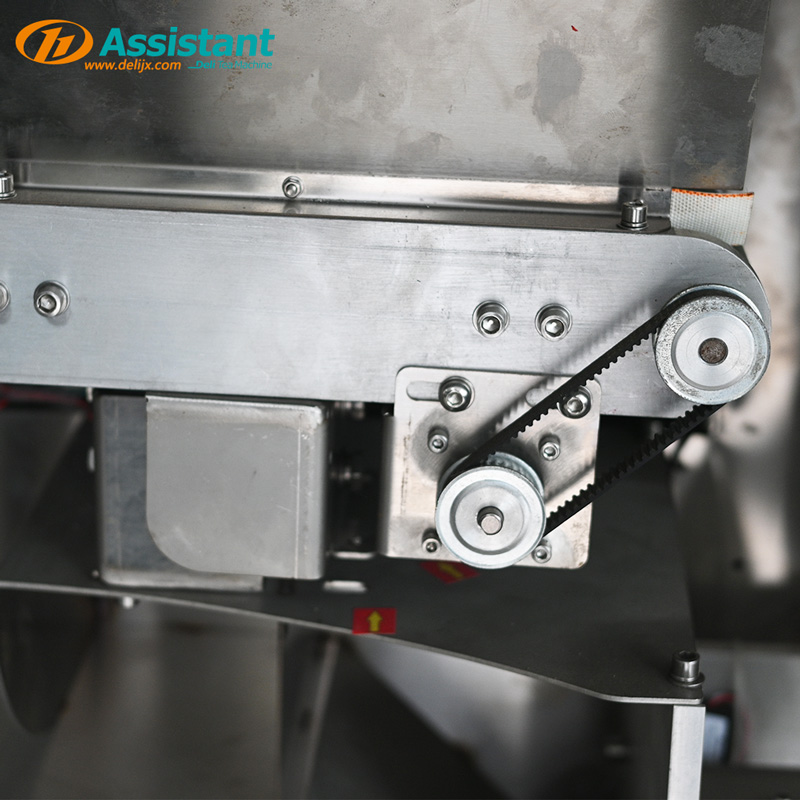

5.Transmission device

Provide power for various components of the packaging machine to enable them to operate normally. The transmission device usually uses components such as motors, reducers, couplings, and transmission shafts to convert the rotational motion of the motor into the linear motion or rotational motion required by various components.

| CONTACT |

If you are interested in this product, please contact us to get the price.

↑ ↑ Click the icon to get the latest price directly ↑ ↑

Tags :