The fully automatic sealing and cutting machine can be used for fully automatic online shrink packaging of products. It uses photo electricity to automatically detect the product. It can be connected to the upstream assembly line for fully automatic heating and sealing packaging, and can package up to 30 products per minute.

Model :

DL-450LSealing Type :

Heat sealingVoltage :

220 V/50 Hz 60 HzPacking Speed :

15-30 bags/minWeight :

280 KGPower :

1.35 KWDimension :

163*90*145 cm| ***DESCRIPTION*** |

| ***ADVANTAGE*** |

1.The sealing knife is made of an anti-stick and high-temperature alloy sealing knife. The outer part of the knife is coated with Teflon non-stick film. The temperature of the sealing knife is controlled by "Xinpu" digital display temperature controller and imported heat-sensitive sensor control. The temperature is adjustable from 0-400°C.

2.The induction switch adopts Japan's famous photoelectric sensor, which can accurately and sensitively detect product delivery and stop, accurately control the waste recycling time, and accurately control the length of film feeding.

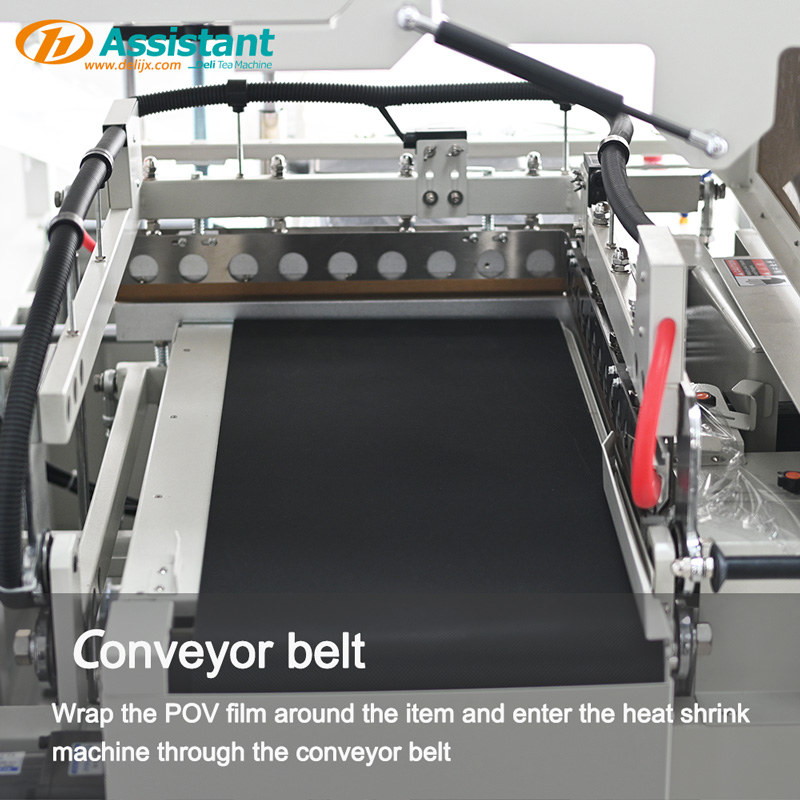

3.Thickened PU conveyor belt is oil-resistant, corrosion-resistant, cold-resistant, and cut-resistant. Not only does it have higher tensile strength than ordinary conveyor belts, good flexibility, lightness, thinness, and toughness, but it is also oil-resistant, non-toxic, hygienic and easy to clean.

4.The use of high-quality motors ensures smooth, accurate and uniform conveying. It has the characteristics of low noise, long life, low energy consumption and superior performance.

| ***SPECIFICATION*** |

| Model | DL-450L |

| Voltage | 220 V/ 50-60 Hz |

| Weight |

280 KG |

| Dimension | 1630*900*1450 mm |

| Power | 1.35 KW |

| Packing Speed | 15-30 bags/min |

| Gas Source | 0.4-0.6Mpa |

| Conveying Load Capacity | 20 KG |

| Maximum Packaging Size H | <150mm |

| Maximum Packaging Size L+H(H<150 mm) | <500mm |

| Maximum Packaging Size W+H(H<150mm) | <400mm |

| Sealing Knife Size L*W(mm) | 550*450mm |

| Shrink Film | POF/PE/PVC |

If you have special need, it can be customized according to the needs of customers.

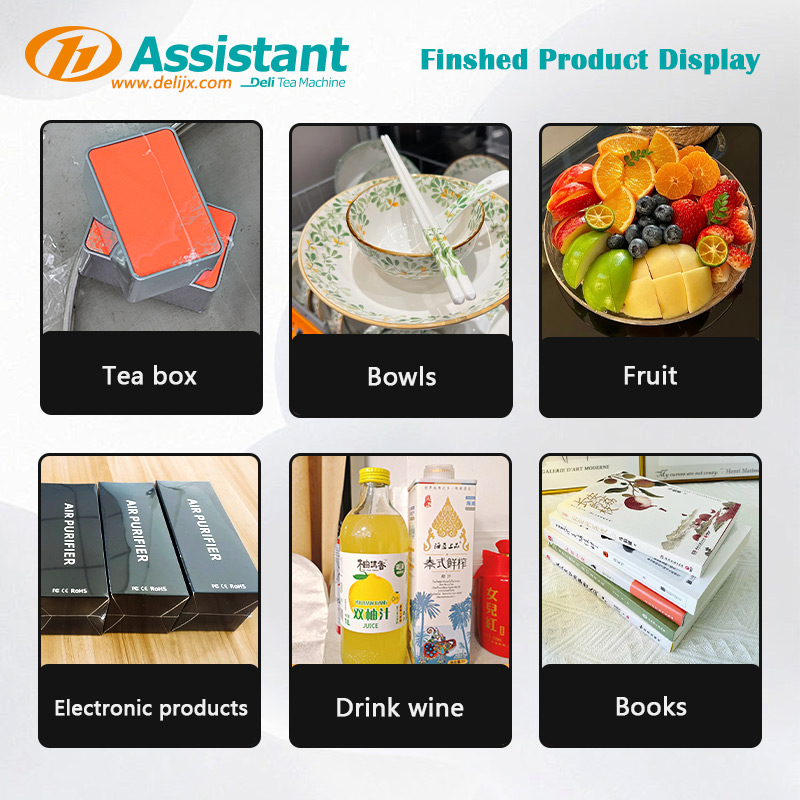

| ***Application*** |

| ***Product Information*** |

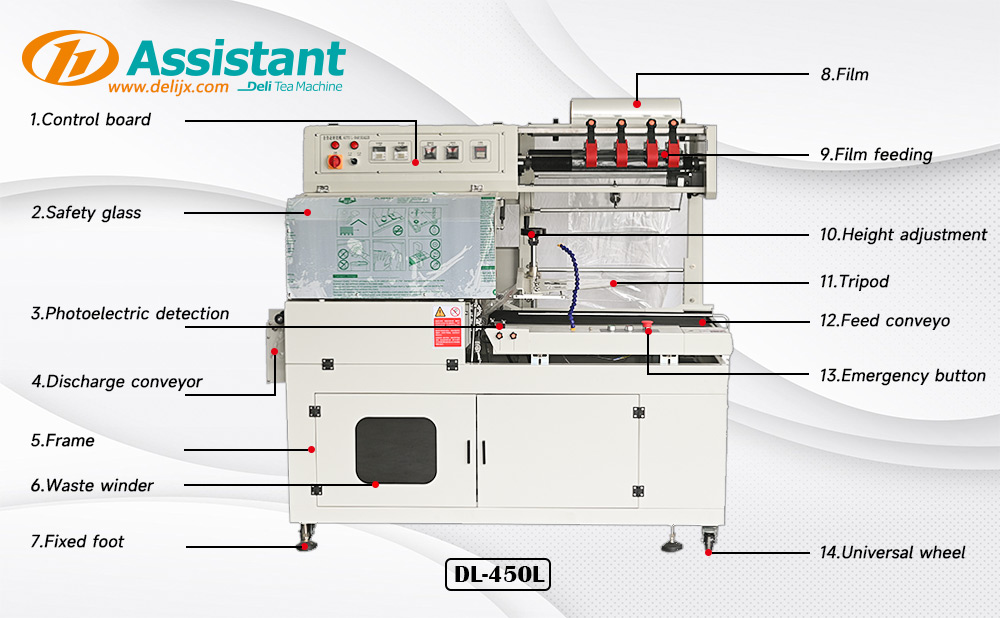

| 1 | Control board | 8 | Film |

| 2 | Safety glass | 9 | Film feeding |

| 3 | Photoelectric detection | 10 | Height adjustment |

| 4 | Discharge conveyor | 11 | Tripod |

| 5 | Frame | 12 | Feed conveyo |

| 6 | Waste winder | 13 | Emergency button |

| 7 | Fixed foot | 14 | Universal wheel |

| ***Product details*** |

01 Automatic operation,simple and convenient

The punching device can be adjusted flexibly,and the brush is designed for permanent use.

02 Durable wide range of application

The inter grated sealing cutter is more durable by Teflon coating.

03 Suitable for most sizes of materials

The membrane separation plate passes through the middle of the double-layer membrane toseparate the two layers of the double-layer membrane. The position of the guide plate can beadjusted according to the shape and size of the product.

04 Recovery unit

Smooth swing, more durable for long-term operation.

05 Film pulling motor

The position of the pin wheel is adjustable,and the pitch of the pin wheel can be adjusted according to the size of the film.The motor pulls the film,which is efficient and safe.

06 All kind of products can be used

Applicable to more industries more products.

| CONTACT |

If you are interested in this product, please contact us to get the price.

↑ ↑ Click the icon to get the latest price directly ↑ ↑

Tags :